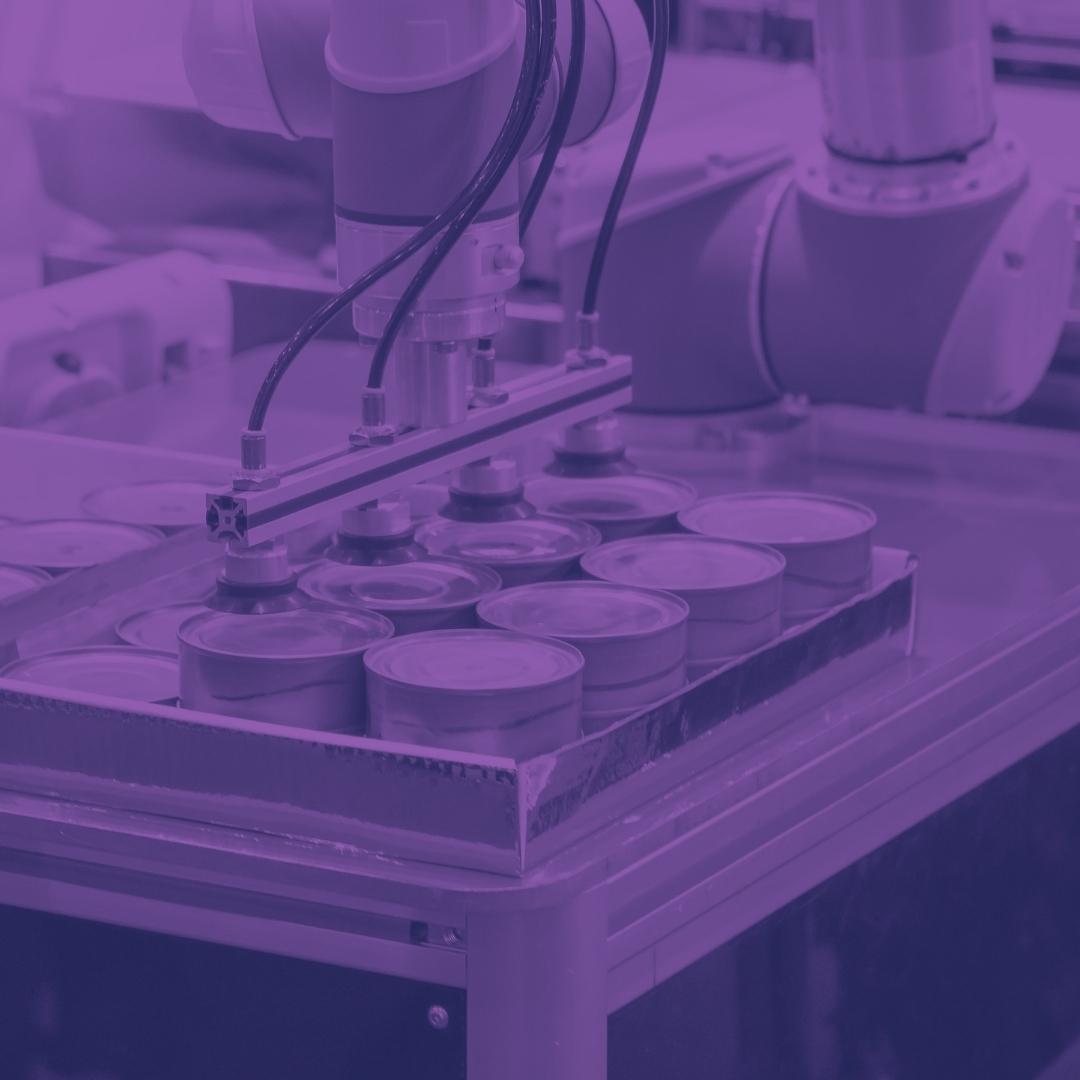

How Are Robots Used In the Food Packaging Industry?

Since the dawn of automation, the food packaging industry has always been a top consumer of robotics for their production lines. The fast-paced food packaging industry works hard to keep up with the growing demands of consumers and recently has been trying to overcome the recent global events and concerns. The food packaging robotics market size is expected to grow by over $1.03 billion in 2022. The COVID-19 pandemic has increased public interest in food safety with many consumers demanding transparency and pushing for more regulations and requirements for food packaging. This public outcry has incentivized companies to eliminate even more human contact from their food packaging production lines. To meet the growing food safety and output demands of consumers, the food packaging industry is once again turning towards more automation.