The packaging industry has seen tremendous growth with new consumer demands and innovations. According to a report by the consulting firm, McKinsey & Company, packaging generates about $900 billion in annual revenues worldwide. Automation has helped push the industry to new heights, saving time and money by automating monotonous processes that gobble up workers’ precious time and resources. A process that commonly gets automated in the packaging industry is tipping.

What is Tipping?

Tipping is a common automation term describing when you take two products and join them together with one product (tipping product) on top of another product (base product). Glue or other kinds of adhesive are used to keep the two products together. The process is used in many different industries, most notably in the food, pharmaceutical, medical, credit/gift cards, and print & packaging industries. In the Credit/Gift Card industry, tipping is used to adhere cards to paperboard backings. In the print industry, web tipping is a process where booklets or folded inserts are placed onto a continuous web to create multi-layer labels. In the packaging industry, a common tipping application is inserting products onto unfolded boxes before they are folded with a Folder Gluer system. A common tipping application in the food industry is tipping pads into the bottoms of meat containers to soak up the excess moisture and liquid.

When not automated, hand placing these products is inaccurate, unrepeatable, and slow. Placing tipping products with an automated system is more productive as a machine can tip faster with accurate and repeatable results. An automated tipping process also allows workers to multitask and focus on more complicated or time-consuming tasks.

There are two ways to automate the tipping process: using a pick & place machine or using a friction feeder.

Pick and Place Tipping

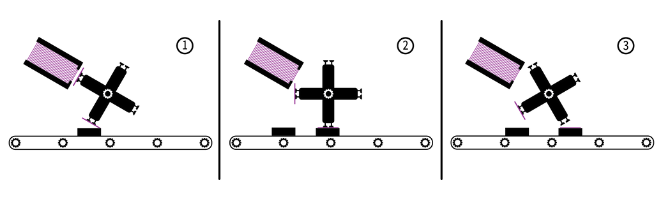

The process for tipping using a Pick and Place can be finicky about product requirements. As the base product moves down a conveyor, a Pick and Place is mounted above the conveyor along with the tipping product. The tipping product is stacked horizontally and the suction cups on the Pick and Place pull the tipping product away from the horizontal stack. The tipping product is then placed on top of the base product.

Tipping with a Friction Feeder

Tipping using a friction feeder is our recommended method. A hot glue system and friction feeder are mounted above a conveyor belt that moves the base products. A line speed encoder detects the speed and positional measurements of the base product traveling on the conveyor belt. As the base product moves down the conveyor, a sensor triggers the hot glue system and applies glue to the base products. The friction feeder is triggered by another sensor to begin feeding after sensing the base product on the conveyor. Feeding speed is controlled and based on data from the conveyor belt’s line speed encoder. To secure the tip-on product onto the base product a pressure roller presses the two products together. This also helps make the tipping product more controllable as it transfers onto the base product, preventing it from shifting or moving before the glue is completely dry.

Below is a short video that summarizes the process of tipping with a friction feeder:

Tipping with a friction feeder is our recommended method as it is more versatile than pick and place tipping. Friction feeders can handle products of different thicknesses, weights, sizes, and textures. In contrast to Pick and Place Tipping, in which the products are stacked horizontally, products are stacked vertically into the friction feeder for tipping. Horizontally stacked products do not need the same level of structural integrity as products that have to be stacked vertically. To be stacked vertically, the products must be rigid, thick, and heavy enough to support itself as it stands in the stack.

In Pick and Place tipping, the suction cups that pick the tipping products out of the stack are particular about the texture of the tipping products. The texture must be flat and non-porous otherwise the suction cups will not be able to stick to the product to pick it up.

Friction Feeders give the tipping product a direct path to the base product. With Pick and Place Tipping, the tipping product must also travel farther on the suction cups as the Pick and Place machine rotates. Using a friction speeds up the tipping process without giving up any precision or accuracy.

Accutipping

Accutipping is MFT Automation’s proprietary tipping software engineered specifically for Multifeeder’s state-of-the-art Friction Feeders. Accutipping software makes micro-adjustments to the speed of the products during the feeding cycle to consistently match the spacing of the base products for precise and accurate placement. These small adjustments make a big difference! The software’s reactive adjustments allow for high accuracy placements while maintaining fluidity and high speeds. The software’s Multiple Tip function allows for a friction feeder to tip more than one product onto a base product, saving money and space as the tipping system won’t need as many friction feeders. Accutipping also has a live placement adjustment feature, permitting adjustment place settings of products without shutting down the friction feeder. Unlike other tipping software, Accutipping's motor controls software has the fine-tuning capability, and various debounce parameters are also available for flexibility.

For even better tipping precision, install Accutipping Repeat to the base product Friction Feeder. Accutipping Repeat was specifically programmed for the base product Friction Feeder to further synchronize the two Friction Feeders in a tipping system. The Accutipping Repeat software uses an encoder for distance information and feeds the base product out at a set distance. This consistent spacing is vital for successful speed matching and can further upgrade the tipping process.

See our Accutipping software in action! Watch this quick demo of one of our Hygienic Friction Feeders Tipping Label Cards onto Meat Containers:

Contact MFT Automation today to find the best tipping solution for your application. Request a quote and send us a sample of your product. We’ll test it for you and then send a complimentary video demo of your product being run through the system.

.png?width=2000&height=600&name=Tipping%20Blog%20Header%20Image%20(2).png)