Manually labeling products works fine at a small production volume but once production increases even slightly, labeling becomes a monumental and tedious task. Automating a labeling system can seem like a daunting investment but the increase in productivity and savings on wages makes the return on investment worth it. Depending on the application, budget, and demand, high-speed labeling is a valuable option for companies to increase their productivity. High-speed labeling is an option for most applications, including labeling boxes, bottles, scratch-off games, Unique Device Identification (UDI) codes, Universal Product Codes (UPC), and more. Just starting your search for a labeling system? This article from PMMI can also get you started on the right path.

There are several automatic labeling methods, but which one is best for high-speed labeling?

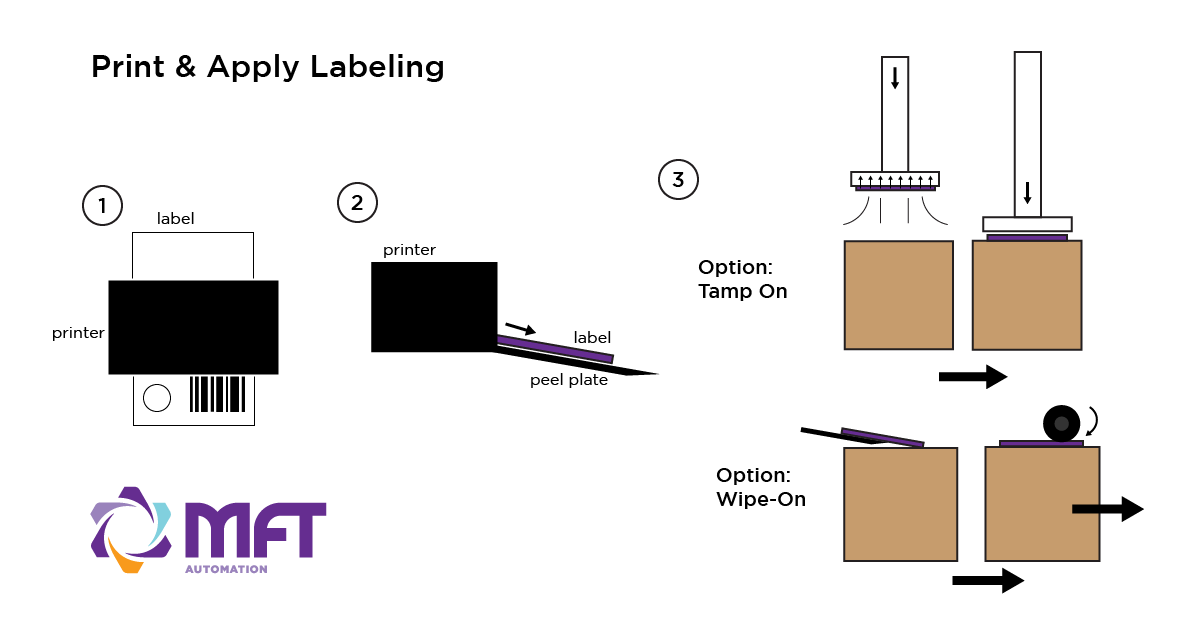

Print and Apply Labeling

Comparatively to other labeling techniques, which use pre-printed labels on a roll, the Print and Apply technique has the labels printed on demand and then applied to the product. Depending on the application, Print and Apply labelers use the wipe-on or tamp-on techniques to apply the labels. But printing new labels for every product, in most cases no matter how fast the printer, slows the labeling process down compared to pre-printed labels on a roll. The Print and Apply method is not recommended for high-speed labeling applications.

Comparatively to other labeling techniques, which use pre-printed labels on a roll, the Print and Apply technique has the labels printed on demand and then applied to the product. Depending on the application, Print and Apply labelers use the wipe-on or tamp-on techniques to apply the labels. But printing new labels for every product, in most cases no matter how fast the printer, slows the labeling process down compared to pre-printed labels on a roll. The Print and Apply method is not recommended for high-speed labeling applications.

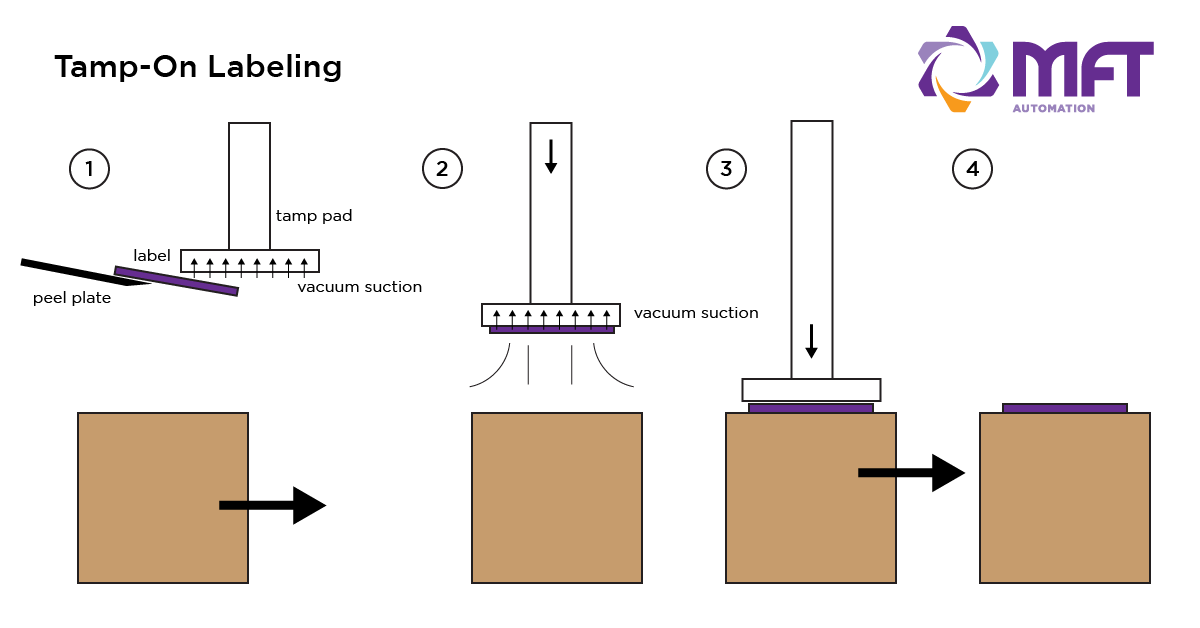

Tamp Labeling

The Tamp label application uses air and a tamp pad to apply labels. The Tamp technique uses vacuum suction to hold the label to the tamp pad until the product arrives underneath via a conveyor belt. The tamp pad presses the label onto the product as it passed on the conveyor belt. With the tamp technique, the smaller the label the faster the tamp pad can place the label. MFT Automation’s Smart Tamp technique accommodates for variation of heights of boxes with a spring-loaded tamp pad that adjusts to the needed height.

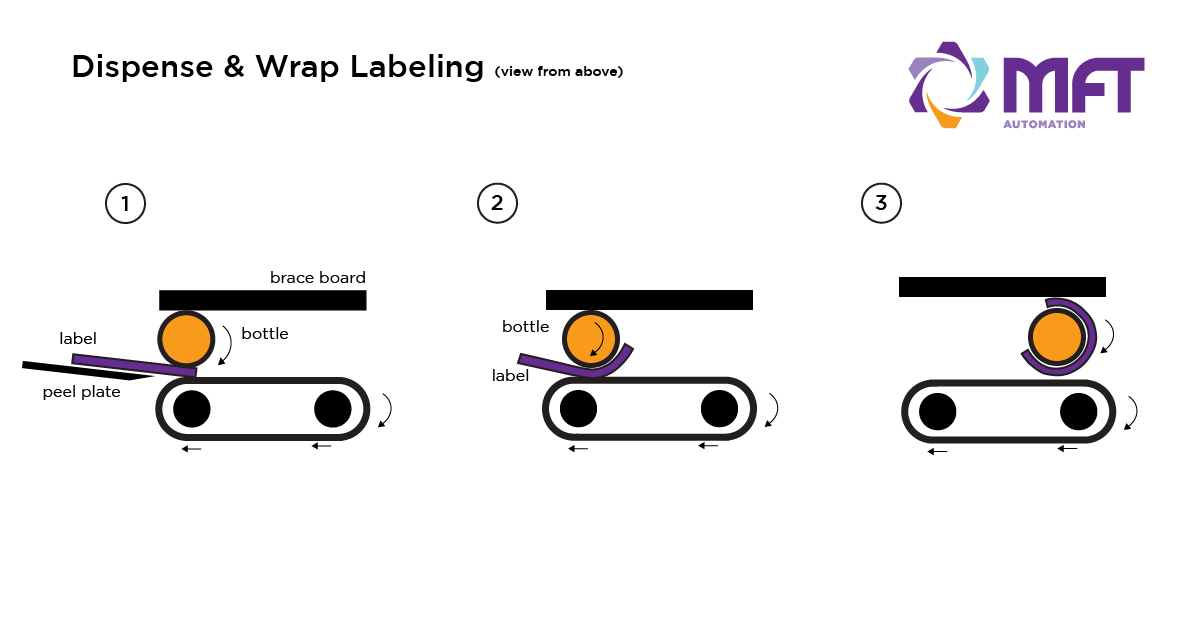

Dispense and Wrap Labeling

The dispense and wrap labeling technique is used when wrapping labels around a product. It is most commonly used for labeling cylindrical products such as bottles of varying sizes, vials, and straight-sided buckets. The product is initially captured in a wrap belt with a stationary backup pad or 3-roller configuration and begins to rotate. While rotating, the label is dispensed off the peel plate in-between the rotating device and the product. The label is fully adhered to during the rotation of the product. While the dispense and wrap technique is the most efficient and accurate way to label cylindrical products, it is not the most efficient or effective way to label non-cylindrical products.

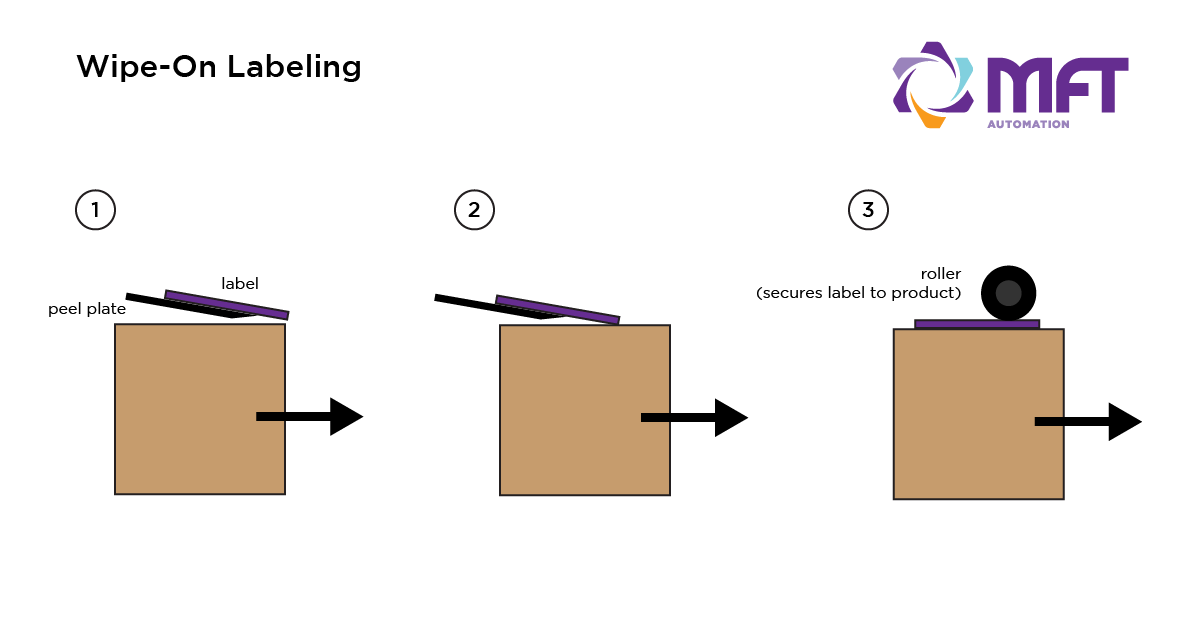

Wipe-On Labeling

Wipe-on is a commonly used pressure-sensitive labeling technique. The label is applied while the product is moving and the label applicator itself often matches the speed of the product as it travels down the conveyor. As the product reaches the labeler, it dispenses the label off the peel plate and the label is wiped onto the product. This labeling technique is often used for oval, square, rectangular, and some irregularly shaped products. Wipe-on is the preferred method for high-speed applications due to its simplicity.

Challenges with High-Speed Labeling

Accurate placement of labels is often a top priority in labeling applications. While wipe-on labeling has the most accurate placement rate of the methods, the high speeds still affect it. Accuracy is dependent on many factors including, maintaining constant tension on the roll of labels as it unwinds to dispense the labels. The tension comes from the dancer arms that maintain tension during unwinding/rewinding of the label roll. High-Speed labelers utilize strong motors to respond quickly to rapid changes in dancer arm position, maintaining tension at high speeds for accurate placement at the peel plate. Accuracy is also dependent on the labeler’s ability to adjust speeds quickly to match the variable speed of the conveyor belt. Adjusting speed can put a lot of strain on the motors as they have to react quickly to match the speed of the conveyor and products.

At high speeds, label rolls tend to be finished faster than when labeling at normal speeds. To keep up with the rate the rolls are used up, companies try to solve the problem by buying rolls with more labels. But just finding the largest roll of labels possible can be dangerous. If the roll of labels exceeds the labeler’s capacity it can have major consequences. Overworking the drive motors can shorten the lifespan of the motor as well as the other parts of the machine. There is also a high risk of damaging the labeler structure with an overweight label roll.

103+ HSM Labeler

The 103 High-Speed Modular (HSM) Labeler is a high-performance labeler built for high-speed labeling applications. Equipped with three independently powered synchronized servo drive motors for unwinding, label placement, and rewind, the 103 HSM quickly adjusts labeling speed to match the speed of the product as it travels down the conveyor. Speed matching is vital for accurate label placement. Three motors also distribute the load and increase the labeler's load capacity. Designed for flexibility, this small, compact labeler works as a stand-alone piece of equipment or can easily be integrated into existing production lines.

About MFT Automation

With over 25 years of experience innovating high-performance automation solutions, MFT Automation is your solution partner for your next automation challenge. Equipped with a diverse team of mechanical, electrical, and software engineers and a modern machine shop, MFT Automation works with you every step of the way from design concept to integration, to create the best solution for your application. Contact us for your next labeling project.