National Engineers Week is February 18-24, 2024, celebrating our nation’s innovators and problem-solvers, past and present. Engineers have been the backbone of progress and change. The engineering field itself has gone through an immense amount of change over the past century. We set out to interview someone who has not only lived through the engineering field’s rapid advancements but also helped contribute innovations to new technology. Lucky for us, our very own founder of MFT Automation, Neal Nordling, was an easy choice.

With the founding of MFT Automation, Neal Nordling has been an Engineer for over 50 years. In those years, Nordling worked in several different industries ranging from aviation to biomedical engineering. Offering an interesting point of view on the vast changes in the engineering field over the past several decades, I sat down with Neal Nordling to chat about his life as an engineer.

Hi Neal, to start can you tell us a bit about yourself?

Nordling: I went to high school in Hallock, MN and graduated in 1961. Hallock is located in a farming community in Northwestern MN about 10 miles from North Dakota and about 15 miles from Canada. My graduating class had 39 members.

I went to the University of Minnesota and completed my Bachelors of Science in Electrical Engineering (BSEE) degree in 1965 and completed my Masters of Science in Electrical Engineering (MSEE) in 1968.

Why did you choose your degree?

Nordling: I wanted to be an electrical engineer since I was in 8th grade. My experience growing up on the farm was probably the biggest catalyst to getting into engineering. We were located, the nearest significant town was East Grand Forks, and the second nearest significant town was Winnipeg, Manitoba. To even go and try to purchase spare parts was a difficult thing. So, we often had to fabricate parts, which we did in my dad's shop. He had a blast furnace, welding equipment, and various cutting equipment. We were able to repair a lot of machinery we ran on our own. In my freshman engineering class, they told us 75% of the engineering enrollees came from a farming background.

What inspired you to be an engineer?

Nordling: My father. On the farm, he functioned like an engineer. Basically, diagnosing problems and fixing problems. Whether it was welding, grinding, or furnace work and then of course electrical problems with engines. My father encouraged me to be an engineer. He talked about going to the University and majoring in engineering but he did not... he graduated from high school but he never had any formal college background. He had a general idea of what the college engineering program was, but he didn’t know much about the specifics of it.

What were some classes you took in college for your engineering degree?

Nordling: Circuits class was my favorite. We synthesized a lot of circuits for various kinds of functions. You knew what you had to accomplish, and you knew the starting point and you knew the endpoint, but you had to synthesize the circuit to accomplish that. And now once again you have programs that help you accomplish that. In those days it was really, essentially, a manual exercise.

We also had Drafting, which they no longer do. In those days drafting was triangles, T-squares, and pencils. Which is far different from today’s equipment. Now all that is done in things like SolidWorks and Pro E or those kinds of programs.

We had very few electives. The engineering curriculum basically allowed you one elective per quarter. So, you’d take 4 or 5 main courses and then one elective. The elective I took was basically the pre-med biology series. I liked that; it was a good course.

What was your first engineering job?

Nordling: I started at Univac in St. Paul. That was more a summer, part time job. I wrote proposals for future business. It was engineering to the extent that a lot of the proposals were based on in-house products, and what needed to be designed to create a finished system. It was engineering but it was a different kind of engineering.

What did you do after you graduated?

Nordling: After I finished at Univac, I then went to Texas Instruments. I worked in the avionics area, aircraft electronics. I was on the team that designed the navigation computer for the A7 aircraft which is a fighter aircraft that operated off of carriers. It was some of the first large scale integration devices that we worked with to create navigation support.

Wow! Please, tell us more!

Nordling: At Texas Instruments, my job was specifically to do the Logic Design for the mathematic functions of the navigations. How you connect the And and Or Gates in order to create a mathematical function. And then I wound up checking out those computers. At the time I lived in Austin, and we had to go up to Dallas and Lovefield. These A7 planes would be coming back from Vietnam, and we had a 4-hour window to install the computer and to check it out, and then to reinitiate the cryptography.

The computer interfaced with the radar system and the radar system gave information on the oncoming terrain, and the idea was similar to following a GPS target, they wanted the airplane to follow a certain contour in the land because they found that to be more successful in terms of flack and all that stuff. The computer at that time was big, it was still one cubic foot, still a pretty small package for a navigation computer at the time.

What did you do after working for Texas Instruments?

Nordling: I came back to the Twin Cities and worked at Data Control. I worked this rotating mass storage, which was magnetic plates storing data, instead of storing data in magnetic cores. One of the problems they had with at the time they were fabricating those discs they had drop out, basically faults in the discs, to solve that problem we had to design an error correction algorithm that would basically be able to correct for a certain amount of missing bits. The first in that time frame that we worked with was eleven bits long. We could correct a hole that was eleven bits in size. We used Coded Message Theory. We basically appended the code onto the data that we could decode, and it would allow us to pick up that many bad bits in a bundle and repair the bundle. That was the first major error correction algorithm that was implemented.

Sounds like you did a lot of programming back in the day. How has programming changed since you started?

Nordling: Programming has changed a ton since then. All the different languages that came about, back in the days when I was doing that kind of stuff, it was very simple languages that they had. Fortran was just coming on but a lot of this was pre-Fortran type days and it was much more elementary and much more down into the basics of the hardware. Individual instructions as opposed to how some of the language-based systems are today.

What was your favorite programming language?

Nordling: I did learn Fortran which was a big upgrade compared to assembly language. Which was Alpha Numonics associated with the different instructions. Rather than calling out an instruction like “65 Octal”, you’d pull it out as a storing operation or a read operation which was using assembly language. Fortran was a real step up from that.

What was your job after Control Data?

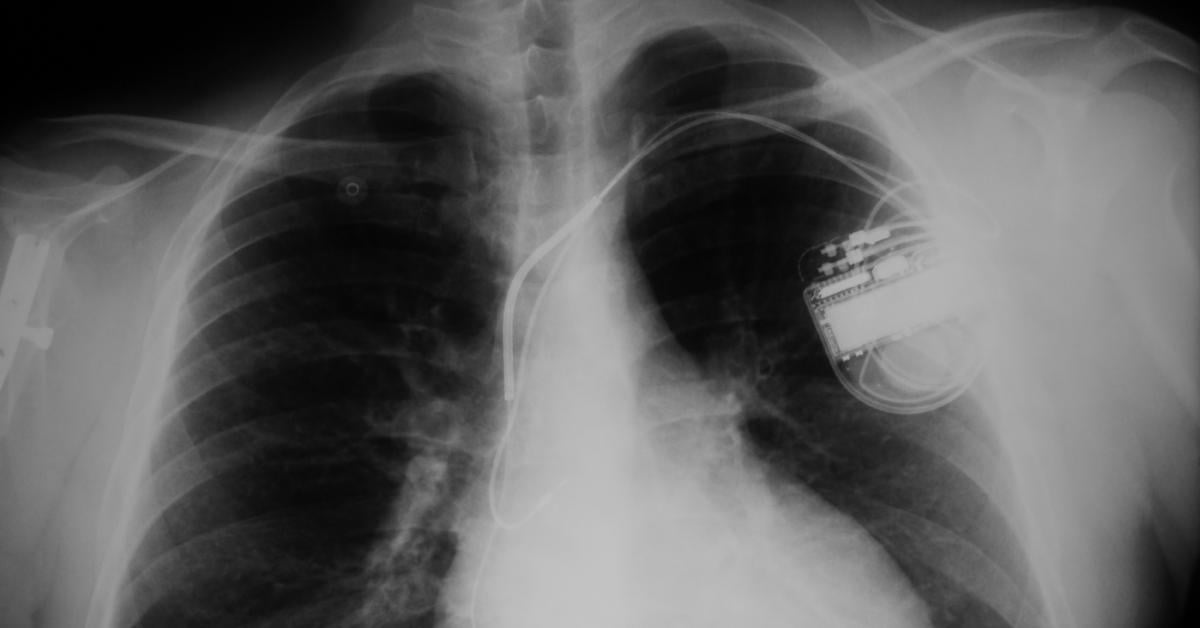

Nordling: I went to Cardiac Pacemakers after Control Data. I ran into a guy at a party that was working at Cardiac Pacemakers, and he was telling me about some of the engineering problems that they had. I got kind of interested in that, partly because even in my college days I liked the biology curriculum that I worked through and at one point I even thought about going to med school but instead, I stayed in engineering. In those days there was no bridging the gap, it was either one or all the other.

When I got to Cardiac Pacemakers one of the problems they had; they had pacemakers that were failing. And it was due to the clock circuit that they had in this one particular pacemaker. I looked at it for about a month and it became apparent that the problem was; the crystal that they used to generate the clock signals was leaking. The leaks were allowing for outside atmosphere to get in and once the atmosphere got to a certain point inside the crystal it would fail. It could no longer do the clock function. So, I hunted around for a different crystal, and it turned out the crystal that was most robust was the one that was used in watches. It was 32 kHrtz crystal and it was used in almost all the watches at one point in time. And the advantage of that is that the tuning fork was much smaller so it could tolerate the leakage that would happen over a long period of time and still function. That was a really satisfying engineering project.

You have a couple of patents under your belt. Do you mind telling us more about them?

Nordling: One major one was at Nonin Medical for the pulse oximeter, which detects non-invasively your pulse and blood oxygen saturation levels. They often use it in surgeries and respiratory care.

We designed it initially to deal with the Sudden Infant Death (SIDs) babies. Initially, we used an impedance pneumography device, and that was partially successful but had a lot of failures. But once we got into the pulse oximeter, things got a lot better. I developed the sensor system and the printed circuit board layout for the pulse oximeter.

What made you interested in starting MFT Automation (previously Multifeeder Technology)?

Nordling: We noticed an opportunity for improvement for friction feeder technology. We researched existing patents and determined that there was a path forward to design a better feeding system. We decided to design the system with full computer control with tight tolerance mechanics and servo motors.

What has made MFT Automation Successful?

Nordling: I think our engineering solutions have been a key ingredient for our success. Clearly that is not the only thing that contributed to our success but one of the most important. We produce engineering solutions for customer problems.

What has been your favorite part of being an engineer?

Nordling: Be able to look at something and see a problem and figure out a solution. That is what basically is what I see engineers do. Often times the implementation or the construction of the solution is relatively easy and straight forward once you have a thought process well defined.

How would you say that engineering field has changed?

Nordling: I think there's far less lab work done. We used to do a lot of work in the lab to prove circuits or do testing. And now there’s a lot of programs that assist with design verification. It was a lot slower to achieve results because a lot of the work had to be done manually. A lot of the calculations were done manually and of course if you had to create test vehicles it was a more laborious type process. The calculator replacing the slide rule was another big change. I bought my first calculator for like $800 and it didn’t do all that much. Even things like programming were more laborious, when we did programming, even at the point where we did a lot of work in Fortran, we had these punch cards. We would have trays of punch cards that you would take down to the data center and they would read them in and run the program for you. Nowadays you sit at your own computer and input the program and run it that way, so you don’t have to do all that stuff. I can remember one of the programs I did. It had a tray of cards that was about four feet long. And if you had to do corrections you had to find the card that needed correcting, and take it out, and key punch a new card. Of course, we cannot forget about the internet and its extensive information source. It has largely replaced catalogs and is used to replace physical library searches.

What future developments in the engineering field are you excited about?

Nordling: There’s a push and pull effecting happening right now. Right now, we’re seeing it here at MFT Automation as we are updating our motherboards. There are so many more devices that we can use that have been developed since the last time we’ve done upgrades to the motherboard and it makes things more complicated but also more versatile and gives the motherboard wider capabilities. New devices that allow for this to happen are appearing at a rate that is increasing substantially. It used to take years to develop these kinds of devices but now they're coming out much more frequently. This is the push to new capabilities.

The old motherboard works fine but there are a lot of limitations because there are a lot of semi-connector parts that these companies are sunsetting. Companies are telling us,

“a year from now you’re not going to be able to buy Part #XYZ”. So, you have to be aware of that and then respond to that. How we respond is basically we either have to find alternative parts that’ll do the job or we have to change the design to do the designed function in a different kind of way.

We’re being pushed from the obsolescent and pulled by these devices with new capabilities. To be competitive in the marketplace you have to keep the product at the forefront by balancing the push and pull.

Any advice for aspiring engineers?

Nordling: Get a well-rounded education.

Any advice for engineers that specifically graduated from college?

Nordling: In general, it's best to go to work for a company that has seasoned engineers that you can learn from and observe. And if you can, stay current on the latest in engineering. Continue taking courses, read periodicals, attend association meetings, tradeshows, and seminars. Becoming a good engineer is an ongoing process that never ends.