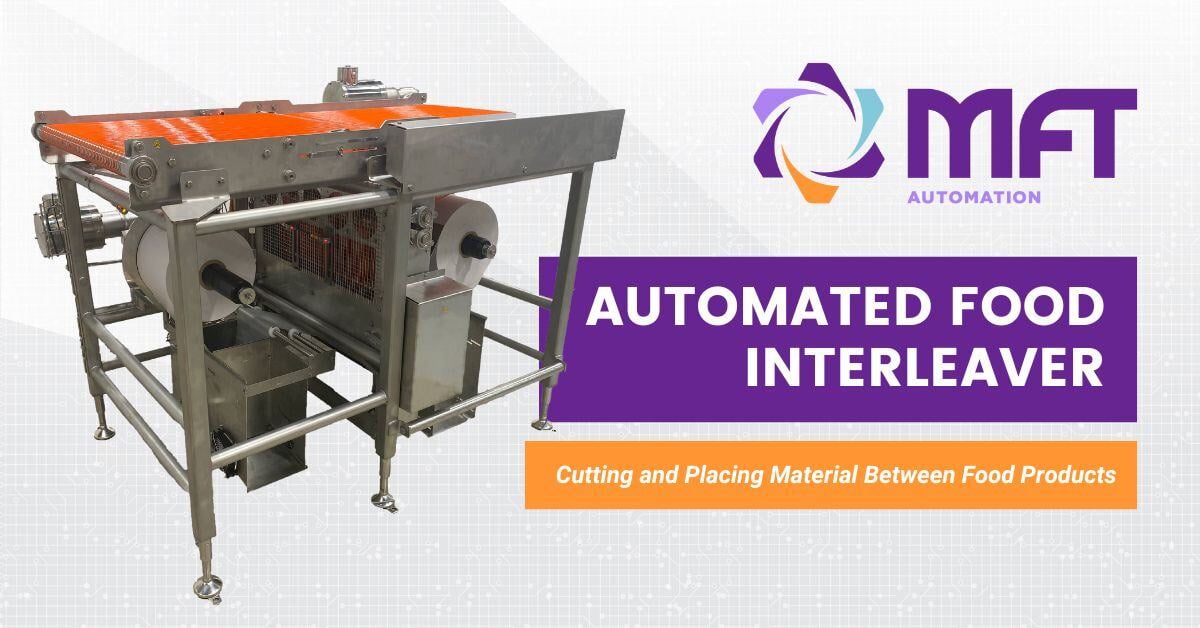

MFT Automation is proud to announce our latest food packaing solution, the MFT Automated Food Interleaver. The MFT Automated Food Interleaver places sheets of paper, film, or foil under food products (underleaving), including burgers patties, deli meat, bacon, tortillas, cookies, pasta, and other food products.

In the food packaging process, human workers often manually package food. The MFT Automated Food Intervleaver reduces human touch points to make the process more hygienic and more efficient. Designed for the Food Packaging Industry with a Washdown design can be washed with harsh chemicals and water without compromising the internal components.

Some key features of the MFT Automated Food Interleaver:

- Non-porous and corrosion resistant stainless-steel construction

- Compact design to easily fit into tight areas and existing production lines

- Configurable to run one or two lanes of products

- High operating speeds with rates up to 80 sheets/min

- Easy to use controls for precise product handling and material cutting

Example Application: Sausage Patties

In this example application, frozen sausage patties are moving on the conveyor belt to the next step in the packaging process. The sausage patties need to have pieces of parchment paper between the patties to avoid them sticking together in the packaging. Usually done manually, the process can be tedious and much slower than if the process was automated. The sausage patties travel down the conveyor belt where a powerful sensor triggers the blade to cut the parchment paper from a roll. After being cut from the roll, the parchment travels up and onto the conveyor belt as the sausage patties are traveling above it. The parchment paper is dispensed between the split between the two conveyors. The moving sausage patties intersect with the dispensed sheets, trapping the sheet between the conveyor and the patties. See it in action:

Learn more about the MFT Automated Food Interleaver

📄 Download the System's Full Specs

☎️ Contact us to discuss automating your food packaging process - call 651-407-3100

Your Food Packaging Systems Partner: MFT Automation

MFT Automation has been in the packaging automation industry for over 25 years providing high-performance automation solutions and services to customers all over the world. Our customer-oriented and engineering-driven process is the key to our success. We start by identifying the customer’s problem and applying our almost 27 years of knowledge and experience in industrial automation to find the best solution. All MFT Automation systems and equipment are designed and built in-house. Our Mechanical, Electrical, and Software Engineering teams directly collaborate with the customer to completely understand the customer’s unique application and to design a solution. Next, our in-house Production Teams work on creating the necessary parts for the equipment. Our machine shop is equipped with modern CNC and lathe machine tools allowing us to offer highly customized equipment and systems. Finally, our Integration Team tests the system relentlessly and puts the finishing touches on the complete system. After integration and installation, we offer abundant after-market services, including training, convenient spare parts ordering, and exceptional customer service.