MFT Automation is proud to announce our newest packaging solution, the MFT Tray Former. Our latest innovation is compatible with MFT Friction Feeders, Robotic technology, and other automation equipment to create a full packaging system. A common bottleneck in packaging production, The tray forming as a manual process can be tedious and the final assembled trays can have varying quality depending on human error and work ethic of the workers. The MFT Tray Former quickly assembles trays with repeatable accuracy and precision for quality results.

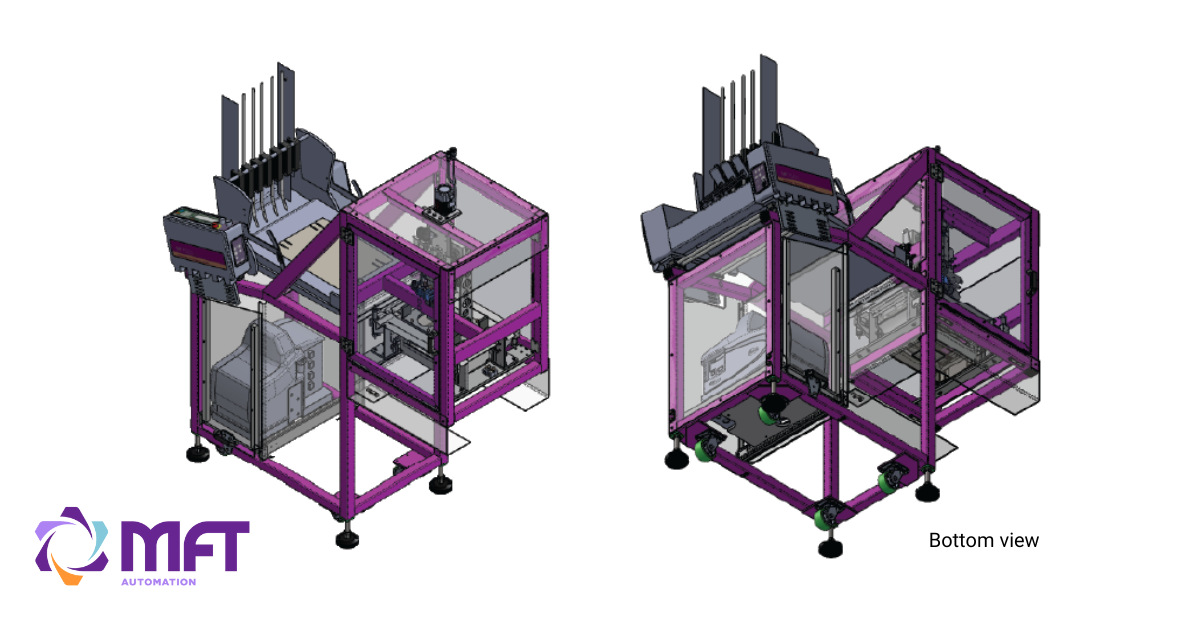

In a full packaging system, the MFT Tray Former increases efficiency, producing assembled trays for the next step of the production process. A servo-driven ram assembly guides tray blanks through the three-stage die assembly to form the tray. The hot glue melt system with Nordson glue guns secures the tabs and siding of the trays. The fully assembled Tray is then delivered to the next step in the packaging process. An example of a common downstream application is pick and place robots insert products into the open tray as it moves past on a conveyor belt.

“We are very excited to introduce this new technology to the market,” said President Peter Nordling. “We have been working very hard behind the scenes to enhance our product lines, and this technology is something we feel compliments our existing product lines perfectly.”

The MFT Tray Former boasts these key features:

- Compact and mobile design - fits into tight spaces and existing production lines

- Built for tough industrial environments

- Compatible with any size MFT Friction Feeder - runs a wide range of product sizes

- Highly customizable to fit specific applications and needs

- Pneumatic flaps with LoTo air supply regulation

- OSHA-compliant safe-guarding with interlocked door

- Accurate count using double-detect and overlap detection

- Hot melt glue system uses Nordson glue gun

📄 Get the full specs and details on the MFT Tray Former: Download the Spec Sheet

MFT Automation

MFT Automation is a world leader in designing and manufacturing automated packaging solutions for the pharmaceutical, medical, food, and beverage industries. Our customer-oriented and engineering-driven process is the key to our success. We start by identifying the customer’s problem and applying our almost 27 years of knowledge and experience in industrial automation to find the best solution. All MFT Automation systems and equipment are designed and built in-house. Our Mechanical, Electrical, and Software Engineering teams directly collaborate with the customer to completely understand the customer’s unique application and to design a solution. Next, our in-house Production Teams get to work on creating the necessary equipment. Our machine shop is equipped with modern CNC and lathe machine tools allowing us to offer highly customized equipment and systems. Finally, our Integration Team tests the system relentlessly and puts the finishing touches on the complete system. After integration and installation, we offer abundant after-market services, including training, convenient spare parts ordering, and exceptional customer service.