In today's fast-paced manufacturing landscape, staying competitive means maximizing efficiency and productivity. One way to achieve this is through the implementation of factory automation. This blog post will delve into three of the areas MFT Automation specializes in friction feeders, labeling machinery, and robotics. By understanding the capabilities and benefits of these automation technologies, businesses can make informed decisions to optimize their manufacturing processes and gain a competitive edge.

Benefits of Factory Automation

Implementing factory automation options such as friction feeders, labeling machinery, and robotics offers several benefits, including:

- Increased productivity: Automation reduces manual labor, speeds up processes, and optimizes overall production efficiency.

- Enhanced accuracy and quality: Automation technologies minimize errors, ensuring consistent product quality and reducing rework.

- Cost savings: By automating repetitive and labor-intensive tasks, businesses can reduce labor costs and achieve long-term cost savings.

- Improved safety: Automation removes workers from potentially hazardous tasks, reducing workplace accidents and injuries.

- Scalability and adaptability: Automation solutions can be easily scaled up or reconfigured to accommodate changing production needs, providing flexibility and adaptability.

Friction Feeders: Enhancing Material Handling

Friction feeders are versatile machines designed to handle the reliable and precise separation of various flat materials from a stack, such as pouches, sheets, cards, envelopes, and labels. These machines use frictional force to separate and deliver materials, a process known as feeding. Friction feeders are found in many different industries and have many different applications including, tipping, batching, counting, insetting, collating, and more. With their adjustable feeding speeds and sizes, friction feeders offer flexibility and adaptability to meet diverse production requirements. By automating the feeding process, businesses can reduce errors, increase throughput, and improve overall process efficiency.

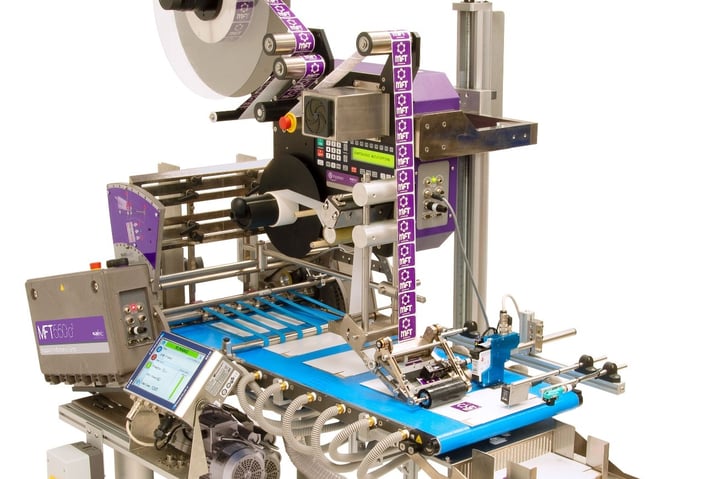

Labeling Machinery: Accuracy and Efficiency in Packaging

Labeling machinery plays a crucial role in packaging operations, ensuring accurate and consistent labeling of products. Automated labeling machines utilize advanced technology, including sensors and precision applicators, to apply labels with precision and speed. Labelers can handle various label types, sizes, and materials, including self-adhesive labels and shrink sleeves. One of the most common labeling applications is labeling for traceability. Millions of companies use barcode labels to track their products through their production processes and to their customers. Automating this labeling process saves time and labor while keeping the product quality up with consistent placement of labels. With automated labeling, businesses can reduce labeling errors, enhance product traceability, and improve overall packaging quality. Additionally, automated labelers can integrate seamlessly into existing production lines, enhancing workflow efficiency and minimizing downtime.

Robotics: Unleashing Efficiency and Flexibility

Robotics has transformed the manufacturing industry by providing unparalleled efficiency, flexibility, and precision. By integrating robotics into automation systems, businesses can achieve significant productivity gains and reduce labor costs. In the context of factory automation, robots can perform a wide range of tasks, such as pick and place, assembly, palletizing, and quality inspection. They’re used in a variety of industries, including the food, packaging, medical, and pharmaceutical industries. Robots take over tedious, repetitive, and even dangerous tasks, freeing up labor to focus on safer and more complicated jobs. Collaborative robots, also known as cobots, can work alongside human operators, increasing productivity and optimizing human-robot interaction. With advancements in machine learning and artificial intelligence, robots can adapt to changing manufacturing needs and perform complex operations with high accuracy.

Integrating Automation Technologies

To fully harness the potential of automation, businesses can integrate multiple technologies seamlessly to create an efficient factory automation system. For instance, friction feeders can work in conjunction with labeling machinery to ensure smooth and stable material handling for more precise and accurate labeling. Additionally, robotics can be integrated with both friction feeders and labeling machinery to streamline the entire process with a full factory automation system. By leveraging the synergies between these automation technologies, companies can achieve a synchronized and efficient process.

In today's competitive manufacturing landscape, embracing factory automation options like friction feeders, labeling machinery, and robotics is essential for optimizing efficiency, productivity, and overall operational effectiveness. By leveraging these automation technologies, businesses can reduce errors, enhance product quality, improve workplace safety, and achieve significant cost savings. Embracing automation not only allows companies to stay ahead of the curve but also positions them for success in an increasingly automated and technologically advanced future.

MFT Automation: Your Factory Automation Partner

MFT Automation is your partner in factory automation. With a wide range of automation equipment, including, robotics, friction feeders, labelers, conveyors, and more, MFT Automation is your one-stop shop for everything from a complete total system solution to standalone pieces of equipment. Robotic integration is the perfect piece to finish off a fully integrated system. As a Mitsubishi Electric Automation Diamond Partner, MFT Automation offers robotic integration services, with capabilities ranging from as simple as pick and place to more complex packaging needs. After almost 28 years in the automation industry, MFT Automation has done successful automation projects in countless industries, including, food, packaging, printing, financial/security, fulfillment, and pharmaceutical & medical. Our experienced Automation Solutions Specialists work with customers to find the best solution for their automation challenge. MFT has an abundance of in-house resources including a machine shop with modern CNC and lathe machines for building equipment to spec. Talented teams of Mechanical, Electrical, and Software engineers, work with customers from the first solution draft to installation and training. Contact us with your latest packaging automation challenge.