Best Automated Labeling Method for High Speed Labeling

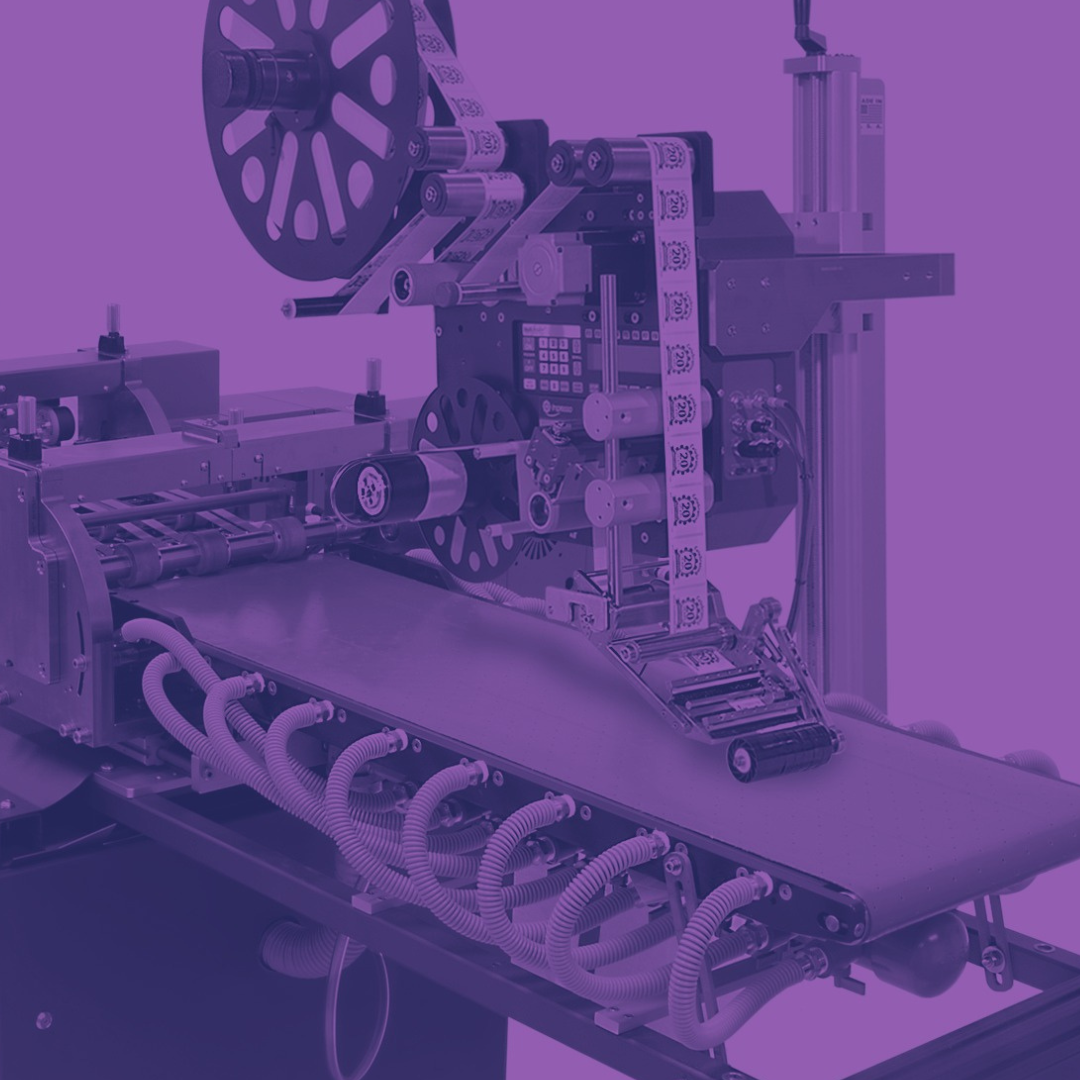

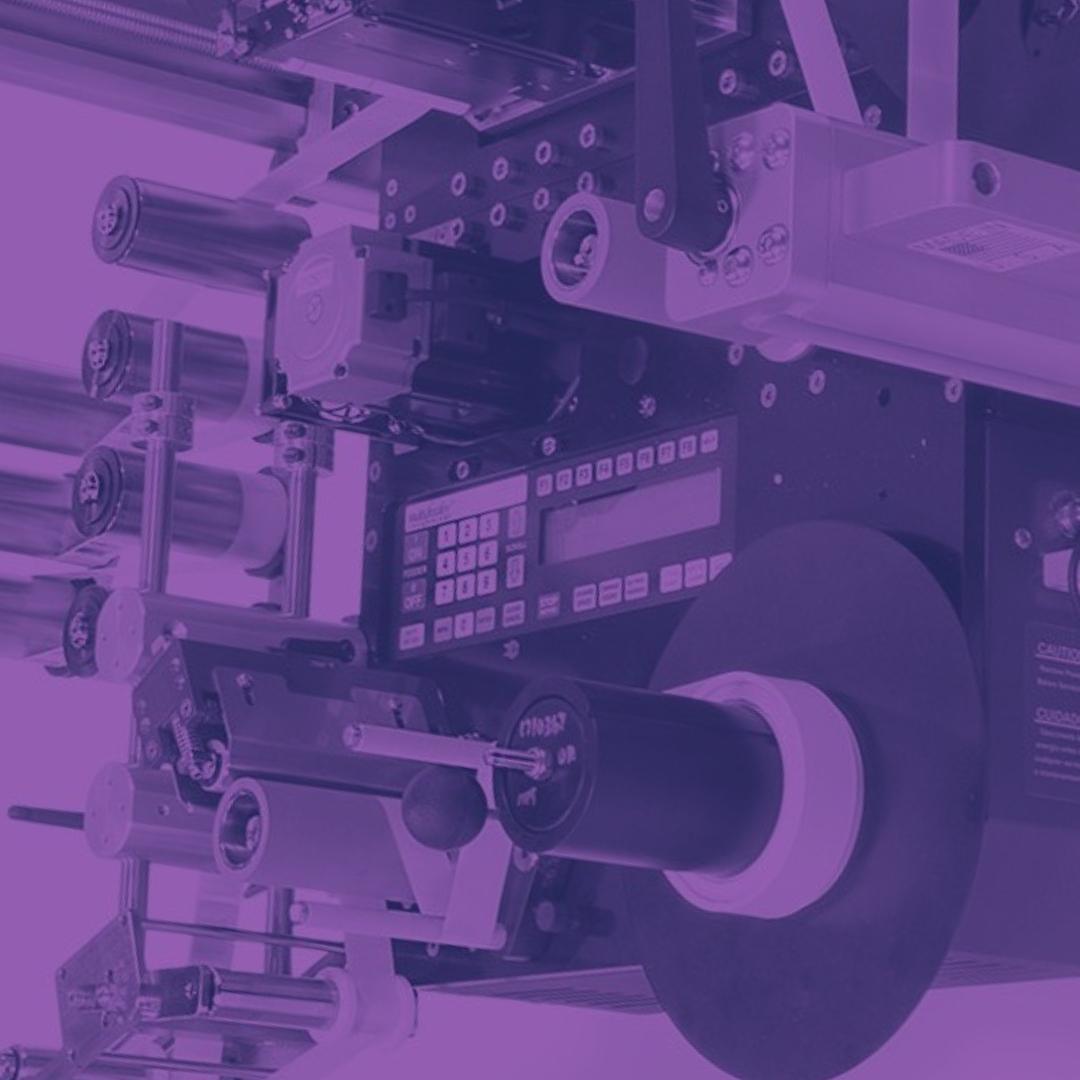

Manually labeling products works fine at a small production volume but once production increases even slightly, labeling becomes a monumental and tedious task. Automating a labeling system can seem like a daunting investment but the increase in productivity and savings on wages makes the return on investment worth it. Depending on the application, budget, and demand, high-speed labeling is a valuable option for companies to increase their productivity. High-speed labeling is an option for most applications, including labeling boxes, bottles, scratch-off games, Unique Device Identification (UDI) codes, Universal Product Codes (UPC), and more. Just starting your search for a labeling system? This article from PMMI can also get you started on the right path.

.png)