The U.S. Centers for Disease Control and Prevention (CDC) estimates that each year 48 million Americans get sick from foodborne illness and an estimated 3,000 die from a foodborne illness. With the rapid evolution of the global food system and supply chain, the U.S. Congress recognized the need for better regulations and guidelines to protect U.S. Citizens and our food supply from contaminations. The Food and Drug Administration (FDA) has been working with the food and food packaging industry to prevent and respond more quickly to contaminations and recalls. The Food Safety Modernization Act (FSMA) puts direct action to prevent foodborne illness. Over the past decade, since being signed into law by President Barack Obama in 2011, the FSMA helped build a new food safety system for the United States of America. After passing the FSMA, the FDA finalized several rules to clarify and specify the responsibilities of every organization in the food supply chain.

One of the major focuses of the FSMA was a better and faster response to food recalls. The FDA addresses this focus with the Final Rule on Food Traceability which outlines how food processors, distributors, and businesses should track their products. The rapid tracking and tracing of food products through the system allows for the FDA to quickly identify the origin of the contamination and any touch points and expedite recalls. Companies and businesses are highly incentivized to carefully trace their food as food recalls can cause billions of dollars in damage from loss in sales to a decline in consumer confidence and reputation.

What is the FDA's Final Rule on Food Traceability?

The Final Rule on Food Traceability (FSMA Section 204) outlines the requirements for additional traceability records for certain foods. Food companies must keep and maintain detailed records containing key data elements (KDE) for specific critical tracking events (CTE) occurring within their supply chain. If the FDA requests these records, the company must provide the information within 24 hours or within a reasonable time. The rule also requires that anyone who must comply with the Final Rule must maintain a Traceability Plan on how they will track and trace their products. The Final Rule on Food Traceability went into effect in January 2023, and anyone subjected to the rule’s requirements must comply by January 2026.

Who must comply with the Final Rule?

Anyone who manufactures, processes, packs, or holds foods that are on the Food Traceability List. There are exemptions for some small farms and small retail food establishments (grocery stores, restaurants, online food retailers, direct farms, etc.), that make less than an average of $250,000 over a three-year period. A full list of exemptions can be found on the FDA website here.

What specific foods need to be tracked?

To clarify the specific foods that apply to Section 204, the FDA established the Food Traceability List (FTL) that identifies foods that are at high risk of contamination for humans. The Food Traceability list includes most raw foods, including:

- Vegetables, including fresh leafy greens, herbs, sprouts

- Fruits, including melons and tomatoes

- Eggs

- Nuts and Nut butters

- Fish, including smoked fish

- Shellfish and Crustaceans, both fresh and frozen

- Cheese

What are Critical Track Events (CTE) and Key Data Elements (KDE)?

Critical Tracking Events (CTEs) are events in a food supply chain that involves harvesting, cooling, initial packaging, shipping, receiving, or transformation of food. Key Data Elements (KDEs) are the wide range of data points that need to be tracked at every CTE. The KDEs are used to describe the CTE, identifying where, when, and what products were involved. The documents associated with these KDEs, include things like purchase orders and advance shipping notifications. KDE records and documents need to be retained for at least two years and be readily available to the FDA in case of an outbreak or recall event. The new requirements will allow for faster identification and expedited removal of potentially contaminated food from the market before they can harm consumers.

What is a Traceability Lot Code (TLC)?

To connect all KDEs across CTEs and beyond, a Traceability Lot Code is assigned to food as it is being packed (after harvest), received, or transformed (consumer food packaging, mixed to make new food). This code must stay the same as it moves through the supply chain unless the food is transformed (mixed into a final product, new packaging, etc.). All food on the Food Traceability List (FTL) needs a traceability lot code for identification information and the food's origin and source. TLCs allow the FDA to quickly identify the source of the food and all the firms that have handled the food.

The food packaging process is considered a CTE (Transformation) and the KDEs need to be assigned a traceability lot code. A trending solution is a 2D data matrix on the food packaging that holds all the tracking information, much more information than a regular UPC barcode. The 2D data matrix on the packaging can not only be used for identification but can also be used for scanning and tracking purposes.

What is a Traceability Plan?

A Traceability Plan is required by the FDA for all persons and organizations that manufacture, process, pack, or hold foods that are on the Food Traceability List. It outlines the procedures and processes for traceability.

Traceability Plans must include:

- Description of procedures used to maintain required records; including format and location of records

- Description of procedures used to identify foods on the FTL

- Description of process of assigning traceability lot codes to FTL foods

- Statement identifying point of contact

- If growing or raising food on the FTL (other than eggs): a farm map showing the areas where food is grown and raised

Traceability Plans must be updated regularly to ensure the information provided reflects current practices and compliance. After being updated, the record of the previous Traceability Plan must be retained for 2 years.

Automation Solutions for Traceability

The FDA does not require a specific application or technology for keeping records but implementing an automated track and trace system is a commonly agreed upon best practice in the food packaging industry. Once implemented track and trace systems are scalable as the business grows and can easily fit into existing production lines. Track and Trace technology uses the 2D data matrices, barcodes and the TLCs read by sensors to track the food products through the system and maintain the records and data. The system improves data quality with highly connected equipment that communicates with each other and automatic data collection in one place.

MFT Automation’s Track and Trace System offers turnkey product handling for serialization coding/printing, and an inspection and reject system providing a trackable data file. The trackable data files are essential to food traceability as FSMA Final Rule requires companies to have the necessary data available for FDA officials when requested. Modular in design, the Track and Trace system can be customized and configured to fit your specific product needs. The system can easily be integrated into existing production lines. An infrared sensor allows for accurate counting using double-detect and overlap detection. This integrated manufacturing system has a highly adaptable software package that ensures flexible and precise controls.

.jpg?width=1200&height=628&name=Track%20and%20Trace%20(1).jpg)

Printing Traceability Lot Codes on Packaging

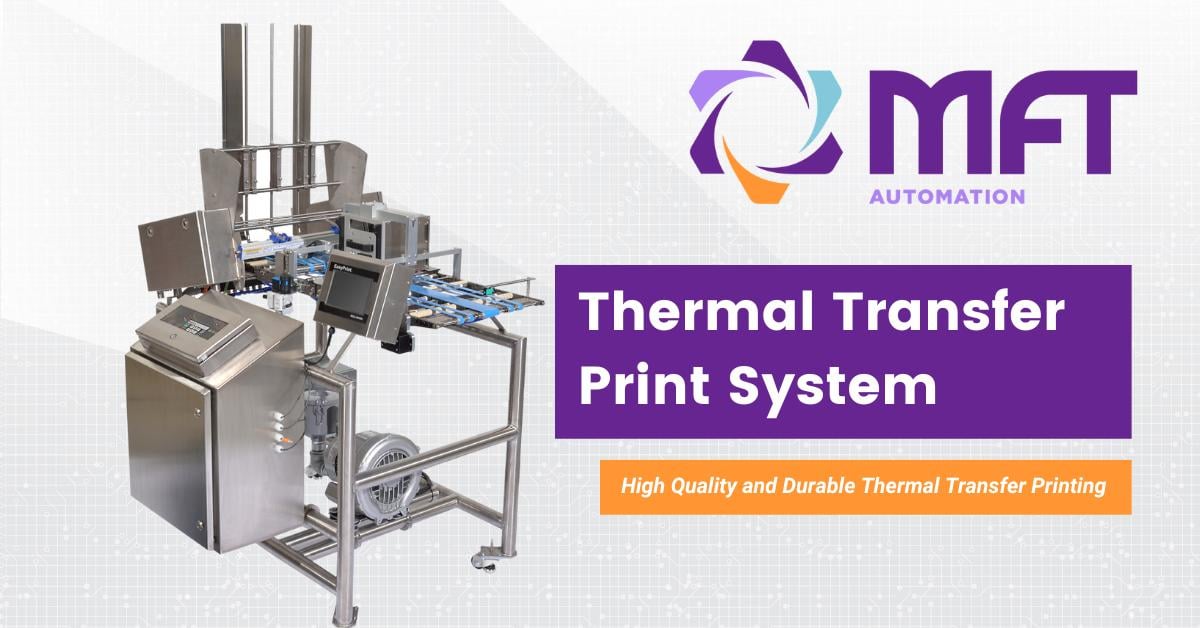

The 2D matrices, barcodes, and TLCs need to be clearly printed or the automatic tracking could be hindered. Thermal transfer print system has fast, clear, and permanent printing for printing on food packaging. The thermal transfer print process uses melted coated ribbon that acts more like glue instead of ink on surfaces for a crisper printed image.

MFT Automation offers an economical and cost-effective Thermal Transfer Print System combining our powerful friction feeders to stabilize products with high-quality thermal printers for clear and accurate print labeling. To accommodate the strict sanitation standards of the food packaging industry, the system can be outfitted with Hygienic Washdown equipment that is specifically designed for environments that need to be kept sanitary. Made with Type 304 Stainless Steel, the material of choice for medical packaging applications, the equipment is designed to be repetitively and aggressively cleaned every day to adhere to safety regulations and guidelines.

MFT Automation: Your Food Packaging Partner

MFT Automation has over 27 years of experience in the food packaging industry, helping customers design, build, and integrate high-performance automation solutions. Our success is made possible by our engineering-oriented and customer-driven approach to finding the best possible automation solution for customers’ applications. With an abundance of in-house resources including Mechanical Engineering, Electrical Engineering, Software Engineering, and a machine shop with modern CNC and lathe machine tools, we work with customers from the first solution draft to installation and integration. Contact us with your latest automation challenge, online or call us at 1-651-412-1873.

.jpg)